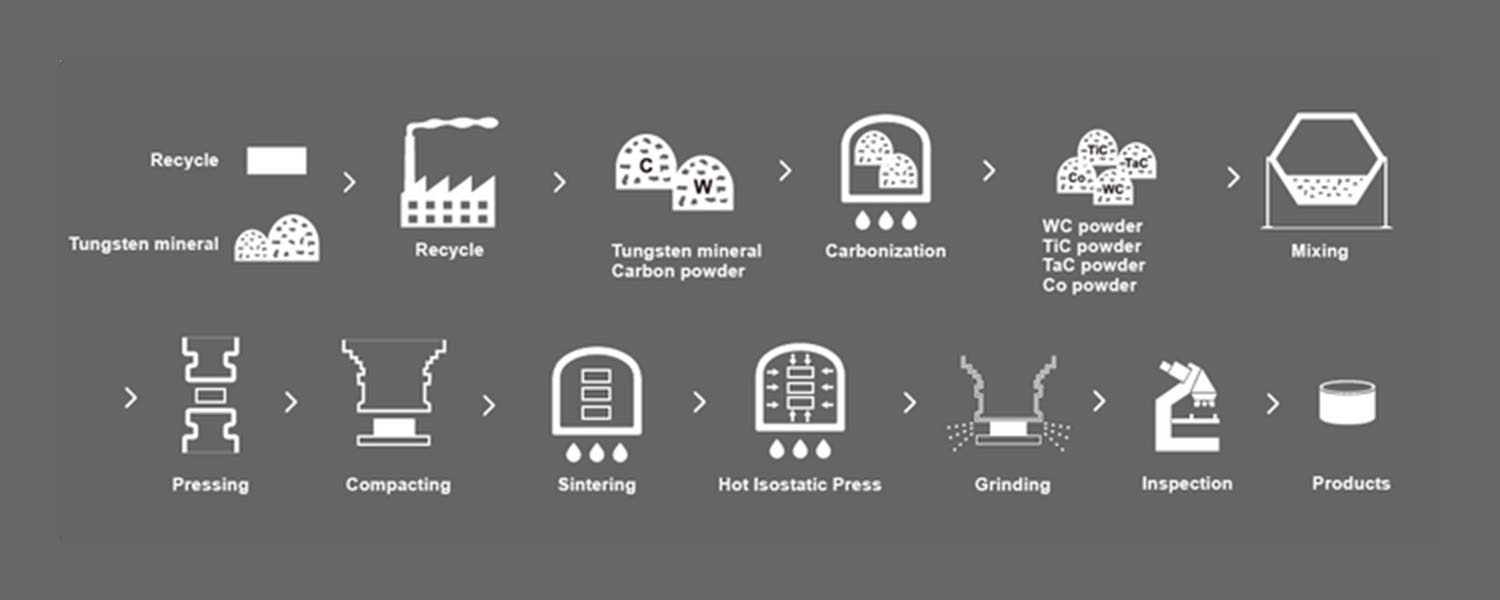

Manufacturing Processes

Manufacturing processes of carbide materials

The excellent properties of high-temperature hardness and wear resistance of our CARBIDE is obtained by sintering its main components, Tungsten Carbide, and a binder, Cobalt, having a low melting point using our high level powder metallurgy technology. In the production process, Tungsten Carbide is first produced, then Cobalt is added, and then compound materials are formed by pressing and sintered in a vacuum sintering furnace.

Mixing / Crushing

Tungsten and carbon are placed in a furnace and heated, they combine to form tungsten carbide(WC). Cobalt and other metal are mixed in tungsten carbide, and the mixture is dried to produce a material powder.

Pressing

The meterial powder is put into a mould and pressed.

Compacting

The geometries are formed by various NC machines.

Sintering / Hot Isostatic Press

The HIP Process is the combination of a novel powder making technique and a hot compaction technique under static pressure. The HIP has been developed and used to produce high-strength, non-porous alloys.

Grinding

High-precision, sophisticated geometries are formed by NC grinding machine.

Inspection

High-performance inspection equipment and experienced engineers ensure the supply of high quality materials.