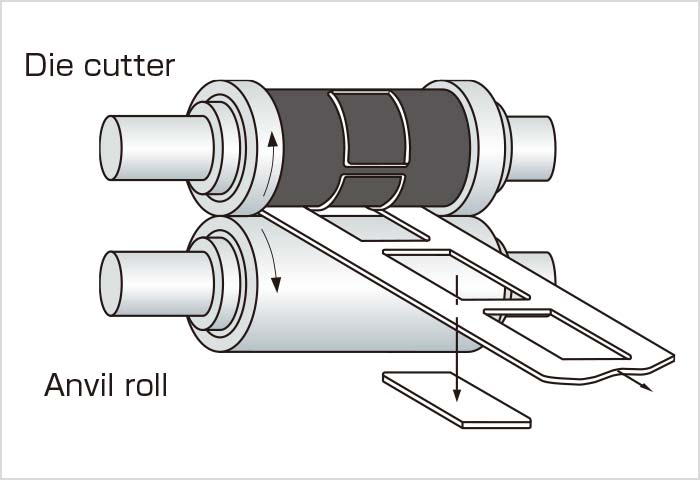

Cutting Tools Rotary Die

The contour cutting tool, rotary die cutter, is essential to the manufacturing of bandages and disposable diapers, used for the hygiene and medical fields.

This cutter has the unique technology to prolong the service life of blade edges. Also, the productivity of our rotary die cutter can be remarkably improved by using with NCU or Pullex unit. In addition, it has been adopted to cut electrode plates used in the battery industry.

Used in a variety of applications such as hygiene, medical care and

clean energy

Paper diapers

Paper diapers Sanitary

Sanitary

products Adhesive

Adhesive

plaster labels

labels Rechargeable

Rechargeable

battery Fuel cell

Fuel cell

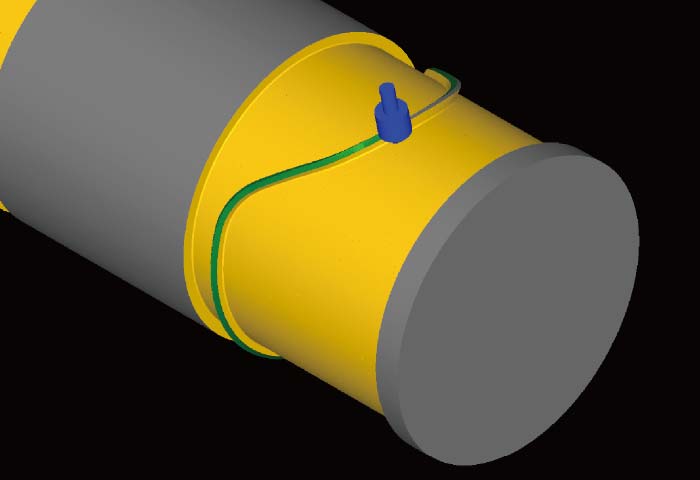

High-precision tungsten carbide cutting edge enables long service

life and high precision cutting

A combination of die cutter with high wear resistance sub-micron grain tungsten carbide, and anvil roll with high impanct resistance tungsten carbide enables long service life and high precision cutting.

MMC RYOTEC's unique analysis technology

We are able to offer the most optimum shape of edge by machining simulation with CAM simulator. Our unique precise grinding and machining technology enables high-precision cutting edge.

CAM simulation

CAM simulation Detail of cutting edge

Detail of cutting edge

Two types of original units contribute to improve productivity

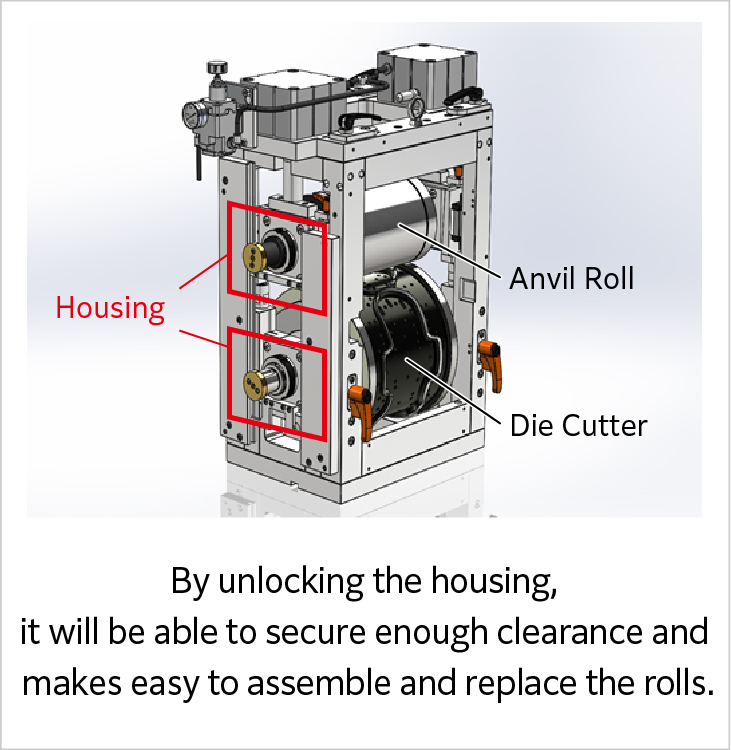

NCU Unit

Easy replacement of the die cutter and anvil roll.

- 【Advantages】

- ・ Easy operation even for beginners.

- ・ Work time reduction for replacement.

- ・ High repositioning in the replacement of the die cutter and anvil roll.

(Note) Unit width requires more than 280mm.

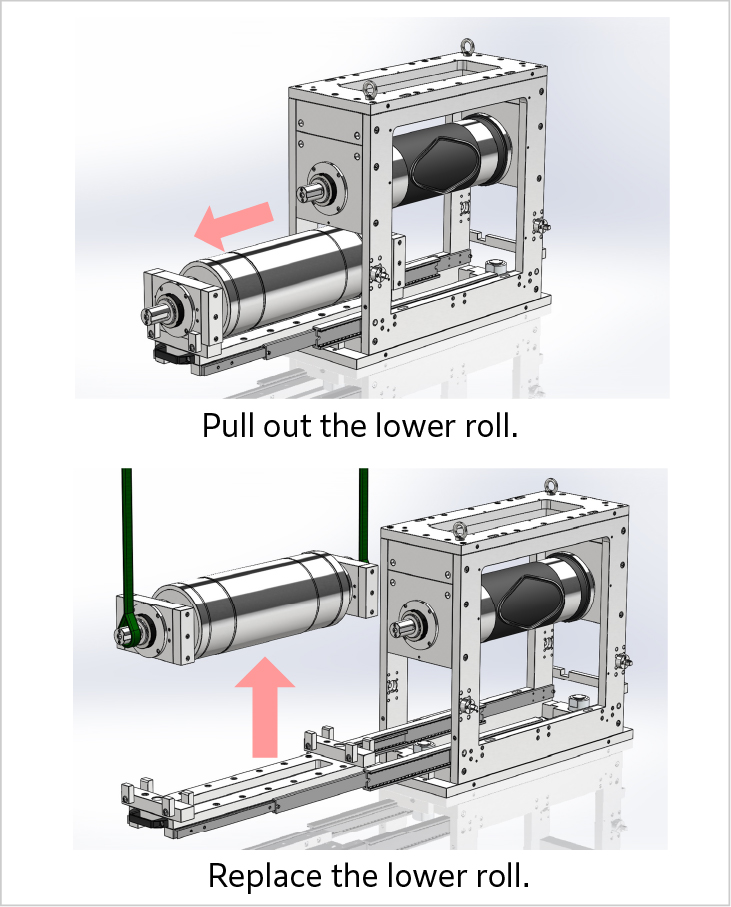

Pullex Unit

"Pull-out method" makes it easy to replace the die cutter and anvil roll on the unit.

- 【Advantages】

- ・ No need to remove the unit from the machine.

- ・ Work time reduction for replacement drastically.

- ・ No extra unit stock. No unit remove.

- ・ Able to replace upper roll by using optional tools.

(Note) Enough working space around the unit is necessary.

Each roll weight must be 200kg or less.

Contribution to improve customer's productivity

Compared to a manufacturing method by using a mold, a rotary die cutting method is able to increase its production speed up to 300m/min, which enables high-speed contour cutting with high productivity.

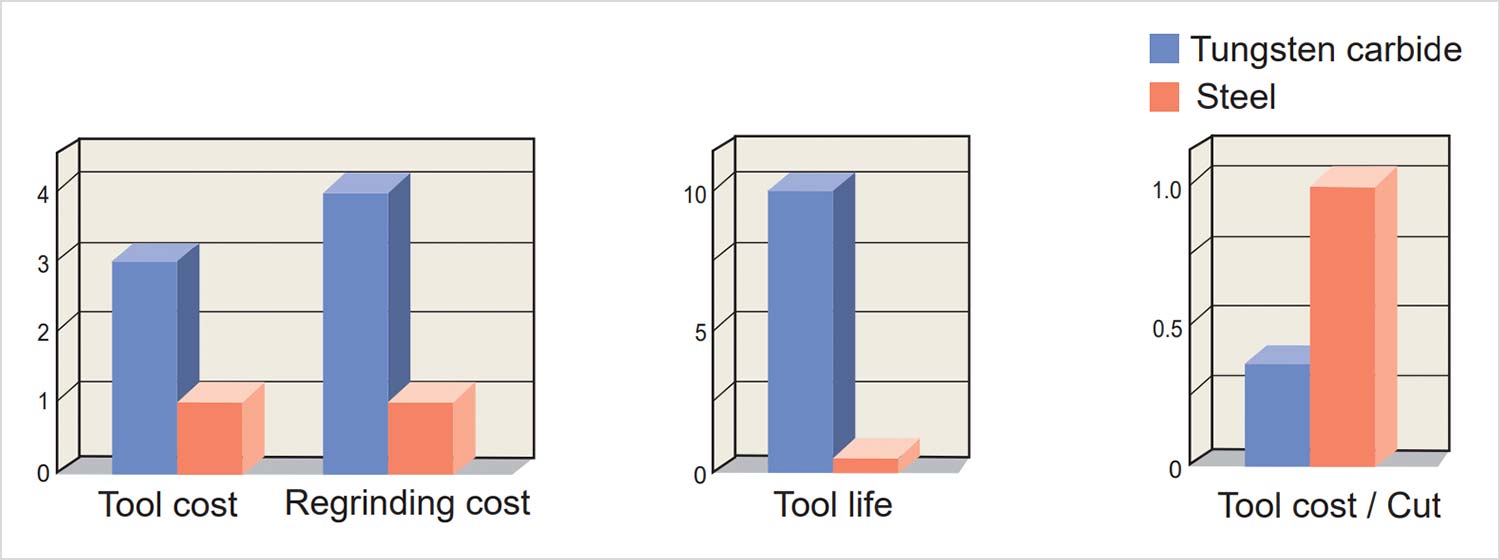

A tungsten carbide cutter costs higher than a steel cutter. However, it has a much longer service life and is able to decrease its running cost down to approximately one third of that of a steel cutter, which will contirbute to improve customer's productivity higher.